Table of Contents

l Introduction

l What Are Waterproof Junction Enclosures?

l What Are Standard Junction Boxes?

l Key Differences Between Waterproof and Standard Junction Boxes

l Best Use Cases for Waterproof Junction Enclosures

l Best Use Cases for Standard Junction Boxes

l Comparison Table: Waterproof vs. Standard Junction Boxes

l Choosing the Right Junction Box for Your Project

l Conclusion

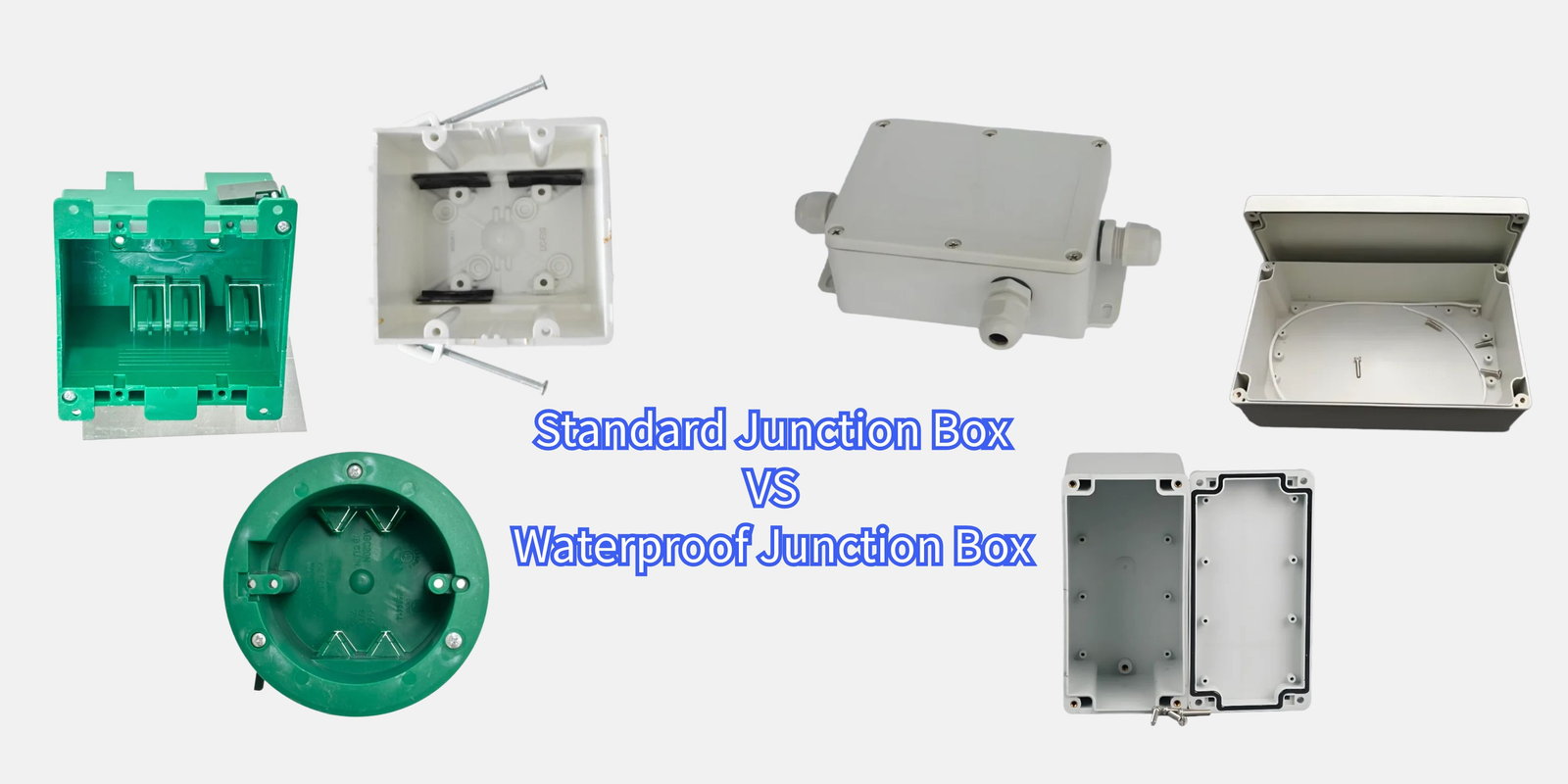

Introduction

When it comes to electrical installations, choosing between waterproof junction enclosures and standard junction boxes can significantly impact the safety, longevity, and performance of your electrical systems.

As a leading US manufacturer of high-quality electrical enclosures, Togalonn understands the importance of selecting the right enclosure for your specific needs. This guide will break down the key differences, ideal applications, and critical factors to consider when deciding between waterproof and standard junction boxes.

Whether you're an electrician, contractor, or DIY enthusiast, understanding these differences will help you avoid costly mistakes and ensure your electrical connections remain safe and reliable for years to come.

What Are Waterproof Junction Enclosures?

Waterproof junction enclosures are designed to provide a secure, weather-resistant environment for electrical connections, especially in harsh or outdoor environments. These enclosures are typically made of high-quality materials such as stainless steel or heavy-duty plastics and are built to withstand exposure to moisture, dust, and extreme temperatures.

Key Features of Waterproof Enclosures:

✔ NEMA 4X or IP66/IP67 Ratedhttps://en.wikipedia.org/wiki/NEMA_enclosure_types

– Provides complete protection against water, dust, and corrosion.

✔ Sealed Gaskets – High-quality silicone gaskets prevent moisture and debris from entering.

✔ Durable Materials – Made from UV-resistant polycarbonate, fiberglass, or 316 stainless steel for long-lasting performance.

✔ Wide Temperature Range – Can operate in extreme conditions (-40°F to 140°F).

✔ Corrosion-Resistant – Ideal for marine, industrial, and outdoor applications.

Common Applications:

l Outdoor electrical panels

l Industrial washdown areas

l Marine and pool equipment

l Underground wiring and conduit connections

These enclosures are ideal for outdoor and industrial applications where moisture protection is essential for the safety and longevity of electrical systems.

What Are Standard Junction Boxes?

Standard junction boxes, also known as electrical boxes or enclosures, are used to house and protect electrical connections in indoor environments. These boxes are typically made of plastic or metal, with less emphasis on water resistance compared to waterproof enclosures. Standard junction boxes are used for applications where the environment is controlled and protected from the elements.

Key Features of Standard Junction Boxes:

l Basic protection: Provides protection from dust and light contact.

l Variety of materials: Can be made from plastic, steel, or aluminum.

l Cost-effective: Generally more affordable compared to waterproof options.

l Affordable & Easy to Install – Cost-effective for residential and commercial wiring.

Common Applications:

Indoor electrical wiring (outlets, switches)

Ceiling light fixtures

HVAC control panels

Office and residential buildings

These boxes are often used in residential, commercial, and light industrial applications where weather resistance is not a primary concern.

Key Differences Between Waterproof and Standard Junction Boxes

Let’s compare waterproof junction enclosures with standard junction boxes in terms of their construction, performance, and ideal use cases.

|

Feature |

Waterproof Junction Enclosures |

Standard Junction Boxes |

|

Material |

Heavy-duty plastic, stainless steel, or aluminum |

Plastic, steel, or aluminum |

|

Waterproof Protection |

High waterproof ratings (IP65, IP66, IP67) |

Limited or no waterproof protection |

|

Corrosion Resistance |

Resistant to rust and corrosion |

Varies depending on material |

|

Use Location |

Outdoor, industrial, marine, wet environments |

Indoor, dry environments |

|

Cost |

Higher cost due to advanced protection features |

Generally more affordable |

|

Durability |

Extremely durable in harsh conditions |

Suitable for controlled indoor environments |

|

Installation |

May require more complex installation |

Easier to install in dry, indoor settings |

Best Use Cases for Waterproof Junction Enclosures

Waterproof junction enclosures are perfect for scenarios where electrical systems need to be shielded from environmental hazards. Some common use cases include:

l Outdoor lighting systems (e.g., street lights, garden lights)

l Marine applications (e.g., boats, docks)

l Industrial machinery (e.g., factories, warehouses)

l Solar power systems (e.g., outdoor solar panel installations)

l Agricultural installations (e.g., irrigation systems)

These enclosures ensure that electrical connections remain safe and functional despite exposure to moisture, dirt, or extreme weather conditions.

Best Use Cases for Standard Junction Boxes

Standard junction boxes are best suited for indoor environments where water resistance is not required. Some of the most common applications include:

l Residential electrical systems (e.g., home lighting, switches)

l Commercial buildings (e.g., offices, retail spaces)

l Low-voltage applications (e.g., networking systems, alarm systems)

l Dry indoor environments (e.g., air-conditioned areas)

These boxes offer an affordable and effective solution for basic electrical protection in environments where moisture and extreme weather are not a concern.

Comparison Table: Waterproof vs. Standard Junction Boxes

For quick reference, here’s a summary of the main differences between waterproof junction enclosures and standard junction boxes:

|

Feature |

Waterproof Junction Enclosures |

Standard Junction Boxes |

|

Water Resistance |

Yes (IP65, IP66, IP67 rated) |

No, limited protection |

|

Ideal Environment |

Outdoor, wet, or humid areas |

Indoor, dry areas |

|

Cost |

Higher due to extra protection features |

Lower cost |

|

Material |

Corrosion-resistant, heavy-duty materials |

Standard materials (plastic, metal) |

|

Durability |

High durability for extreme conditions |

Standard durability |

|

Maintenance |

Low, due to protective seals |

Low, but may need maintenance in dusty environments |

Choosing the Right Junction Box for Your Project

Ask Yourself These Questions:

l Will the box be exposed to rain, humidity, or extreme temperatures? → Waterproof

l Is it for indoor residential/commercial use? → Standard box

l Does the environment have dust, chemicals, or saltwater? → Waterproof (NEMA 4X)

l Is budget a major concern? → Standard (if indoor only)

Pro Tip: For outdoor or industrial projects, investing in a high-quality box from Togalonn prevents costly repairs down the line.

Conclusion

Standard junction boxes and waterproof enclosures each have their own advantages and are made for different applications. Standard junction boxes are a more economical and effective option for indoor electrical projects in controlled environments, while waterproof enclosures are the best option if you need dependable protection from the elements.

At Togalonn, we specialize in offering high-quality junction boxes that are customized to meet your specific needs, whether you're looking for standard boxes for residential projects or waterproof enclosures for outdoor use.

Contact us today to explore our range of junction boxes!