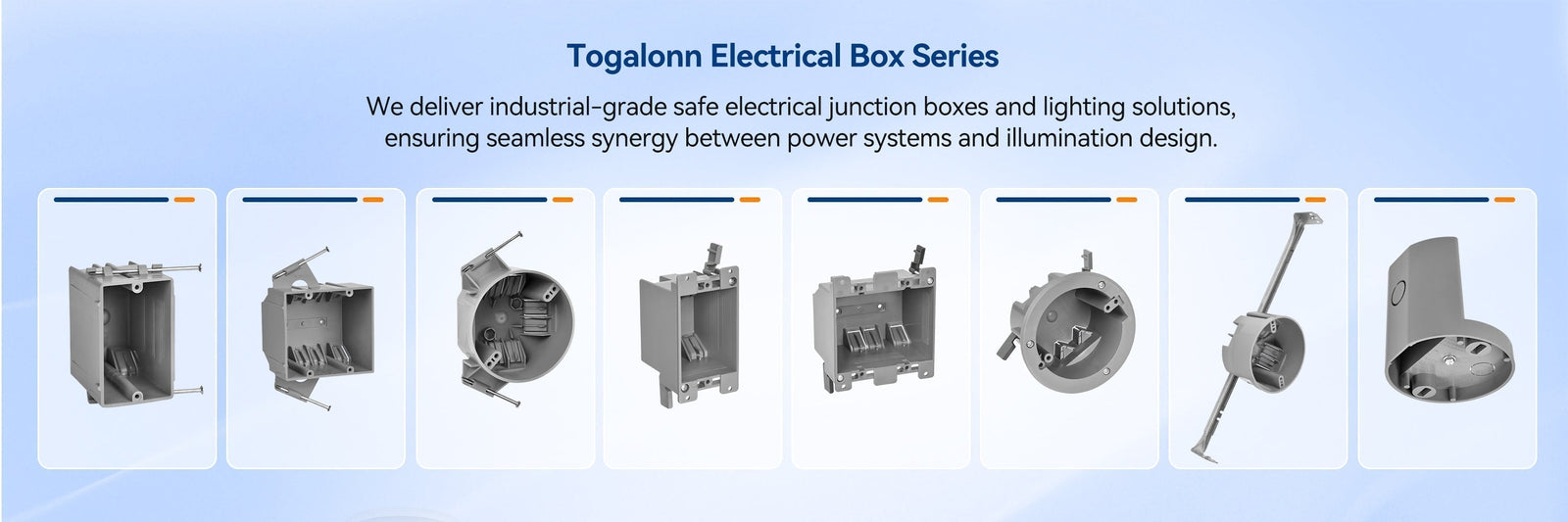

This article will provide a detailed introduction to various types of junction boxes, including new work junction boxes, old work junction boxes, fan junction boxes., we will analyze their features and suitable applications. Additionally, a practical junction box guide will be provided to help you better understand the functions and selection criteria for choosing the right junction box.

Table of Content

1. Being familiar with the various types of electrical boxes

Being familiar with the various types of electrical boxes

Ideal for: Wire splices that are enclosed

1.1 Junction Box

Wires never link to a switch, outlet, or fixture—only to one another. permits the safe division and branching of circuits in various directions.

The most popular junction box is a square box made of sturdy plastic or metal that provides plenty of room for connecting several wires or cables. Junction boxes can be made from a variety of box kinds.

Ideal for: Unfinished drywalls (open walls)

1.2 New Work Electrical Box

New work boxes are used for brand-new building project,for installations in uncovered walls or ceilings .Before drywall is applied, it can be attached directly to studs or joists, even bridged between two studs with a bar hanger.

Ideal for: Walls that possess existing drywall(enclosed walls)

1.3 Old Work Electrical Box

Old work electrical boxes are meant for installation in completed walls without disrupting your drywall. Also regarded as “shifting box” and can be quickly set up with minimal effort.

Ideal for: Light fixtures placed on the wall or ceiling that weigh up to 50 pounds

1.4 Round Ceiling Box

These days, ceiling boxes are an essential installation of any projects. They are made to work with a variety of lighting fixtures, smoke alarms, and gas sensors. The box also useful by giving stability and support to fixtures.

Ideal for: For ceiling fans and fixtures(14.25in.to 23.5in.) on center joist applications

1.5 Ceiling Fan Electrical Bracket

To secure the fan in place, a ceiling fan supporting bracket enhances the junction box's structural stability. Setting up a combined support hanger or junction box doesn't necessitate many tools or extensive demolition.

1.6 Heavy Fixture Ceiling Box

It is made of impact-resistant thermoplastic, virtually unbreakable and non-conductive.Note this is suitable for lights but not for fan mounting.

Ideal for: For ceiling fixtures(14.25in.to 23.5in.) on center joist applications(not for fans)

1.7 Outlet Box Extender

Ideal for: Enhancing box volume and ensuring boxes are aligned with adjacent surfaces.Electrical box extenders are a fantastic option if the outlet is loose because they are affordable and simple to install for switches and outlets.

1.8 Shallow Electrical Box for Ceiling Fan

Ideal for: Suitable for ceiling fans, light fixtures,fire alarms and smoke detectors.An excellent option for new work applications is the Shallow Ceiling Pan Electrical Box. It is made especially to hold light fixtures and ceiling fans that weigh up to 110 pounds and 75 pounds.

1.9 Ceiling Fan Box

Ideal for: A heavy-duty plastic electrical box that works with any type of ceiling fan.This non-metallic L-shaped fan and fixture mounting box is also known as a saddle box.For 150 pounds of fixtures support and ceiling fans that weigh 70 pounds.

1.10 Weatherproof Junction Boxes

Ideal for: Against moisture, dust and debris, protects electrical connections. Any outdoor setting should have electrical connections protected. These enclosures offer outlets, switches, and other electrical components a safe haven since they can weather rain, snow, intense sun, and persistent dust.

Tips:A junction box should not be placed in a concealed wall or ceiling area that are inaccessible. Additionally, the junction box should be equipped with robust enclosures.

Considerations for Selecting the Correct Electrical Box

2.1 Material and Location

The surroundings has a big influence on the material you use.The main components used to make electrical boxes are steel, PVC, fiberglass, and cast aluminum.

a) Steel: Suitable for nonmetallic-sheathed (NM) cable with proper fittings, steel is also perfect for indoor use with all conduit types and metal-clad cable.

b) Cast Aluminum: This material is perfect for humid or wet indoor environments as well as outdoor use in weatherproof applications.

c) PVC: For using nonmetallic-sheathed (NM) cable, PVC boxes work best indoors. Electrical nonmetallic tubing (ENT) and NM cable can be utilized with PVC boxes that include knockouts.

d) Fiberglass: Typically combined with nonmetallic-sheathed (NM) cable, fiberglass is ideal for interior use.

2.2 Box Capacity

Selecting the appropriate size of the electrical box is the most critical factor in ensuring its adequacy. Each box has a maximum capacity measured in inches. When the electrical box is overfilled, it can lead to hazardous situations,a great advice is to select for a larger box.

Reference Example:

Number of devices: 2 switches + 1 outlet

Number of wires: 6 x 10 AWG wires

Wire size: 10 AWG (cross-sectional area approximately 5.26 mm²)

Junction Box Volume Calculation:Each 10 AWG wire requires approximately 2.50 cubic inches of space.The total space required for 6 wires:

6 × 2.50 = 15.00 cubic inches.

Additional space needed for device connections: approximately 6 cubic inches.

Recommended Size: Choose a junction box with at least 21 cubic inches of capacity.

2.3 Connection technique

The connection technique of the junction box must be evaluated in advance. Certain junction boxes use screw terminals for wire connections, whereas others utilize crimp connections. Crimp connections necessitate specialized tools and expertise to ensure greater reliability.

2.4 Safety certification

Choosing junction boxes that possess UL-related safety certification guarantees adherence to safety standards.

In Summary

Installing a junction box, which joins the power and light lines of small electrical accessories, can greatly simplify the process of installing fixtures. When choosing a lamp junction box, you should take into account the environmental regulations as well as the material, model, and specifications that are suitable for your needs.

FAQ

1. Why are Junction Boxes Essential?

A junction box is an electrical enclosure designed to contain multiple wire connections, safeguarding wire joints and other vulnerable points from environmental conditions and accidental contact. It optimizes circuit layout and minimizes electrical accidents caused by wear, corrosion, or unintended contact.

2. What is the primary function of an electrical box?

A distribution box is a device used for the protection and distribution of electrical power. It features safety protection functions, stable structures, and convenient maintenance, allowing for quick disassembly and replacement.

3. Does a junction box provide power?

The junction box does not directly deliver power, it is used to connect the power source to electrical devices. The junction box provides a secure connection point for linking wires to outlets or other electrical equipment.

4. Are electrical boxes similar to junction boxes?

The primary distinction between an electrical box and a junction box is based on their specific purposes. An electrical box is intended to accommodate switches, outlets, dimmers, while a junction box is not intended to involve any electrical devices. Instead, the junction box functions exclusively as a connection and junction point for electrical cables.

5. Method of Wiring?

Your decision is also influenced by the type of cable you plan to use. While metal-clad cables require metal boxes, non-metallic cables work well with plastic boxes.

Whether you're tackling a new construction project or updating an existing setup, choosing the right electrical box ensures safety, efficiency, and compliance. From junction boxes for secure wire connections to fan-rated ceiling boxes for heavy-duty support, the right choice makes all the difference.

Have questions? Contact our experts for personalized recommendations!